Precia-Molen UK registers with Weighing Review

Precia-Molen UK Ltd has recently registered with Weighing Review, the leading global resource for the weighing Industry and the main source for Weighing Industry News. For more information, please […]

At Precia we understand that the smooth day to day running of your business is paramount. That’s why we offer an affordable aftercare plan that delivers excellent customer service on time, every time.

Our highly qualified engineers are certified to work in a broad range of environments. These include laboratories, food processing, and chemical plants, construction sites and quarries.

We’d be delighted to discuss Service Plan options with you. Please call 0333 300 1852 or complete the Contact Us form to talk to a member of our team.

Find out moreFind our solutions for your industries

Precia-Molen UK Ltd has recently registered with Weighing Review, the leading global resource for the weighing Industry and the main source for Weighing Industry News. For more information, please […]

Did you know that PRECIA MOLEN is involved in putting satellites and rockets into orbit? We explain how in this article. What is propellant? What is the link between PRECIA […]

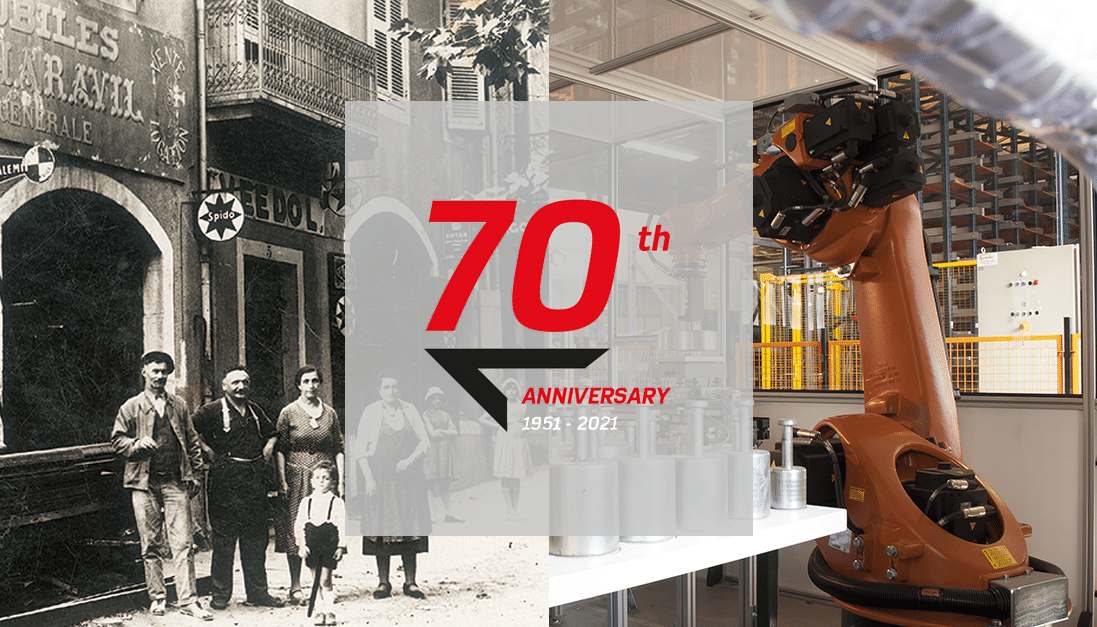

In 2021, PRECIA MOLEN celebrates its 70th anniversary. 70 years of innovation From the weighing indicator that will meet your future needs to the transition towards a connected industry, […]